Why Pipeline Welding Inspection is Essential for Long-Term Pipeline Safety

Why Pipeline Welding Inspection is Essential for Long-Term Pipeline Safety

Blog Article

Ideal Practices for Pipeline Welding Examination: Techniques, Standards, and Procedures to Achieve Quality Assurance and Conformity

Effective pipe welding evaluation is vital for making sure the integrity and safety of essential facilities. By employing a mix of strategies such as aesthetic inspection and progressed non-destructive screening approaches, along with adherence to established industry requirements like those from ASME and AWS, companies can substantially improve their high quality guarantee procedures. Nevertheless, the execution of these best methods positions various challenges that warrant careful factor to consider. Recognizing the intricacies associated with each stage of evaluation is vital to attaining conformity and integrity in pipeline systems. What certain techniques can be employed to navigate these obstacles efficiently?

Importance of Welding Inspection

The stability of welded joints is vital in making sure the security and dependability of pipeline systems. Appropriate welding techniques and extensive inspection procedures are essential to stop failures that can bring about tragic events, ecological damages, and death. Pipeline Welding Inspection. Welding inspection functions as a safety net, identifying defects such as cracks, porosity, and insufficient fusion prior to they intensify right into serious concerns

Furthermore, pipe systems often run under high stress and severe problems, making the top quality of welds a lot more essential. Regulatory compliance is an additional substantial element, as different requirements dictate the quality control processes that must be complied with in pipeline construction and maintenance. Failure to conform can result in legal implications and financial losses.

The role of welding inspection extends beyond plain confirmation of handiwork; it encompasses the guarantee of long-term operational honesty. This includes a methodical technique that consists of not only aesthetic evaluations but additionally advanced non-destructive testing methods. Ultimately, effective welding examination is a financial investment in the durability and security of pipeline systems, guaranteeing they work as meant while decreasing dangers connected with material deficiencies.

Secret Examination Strategies

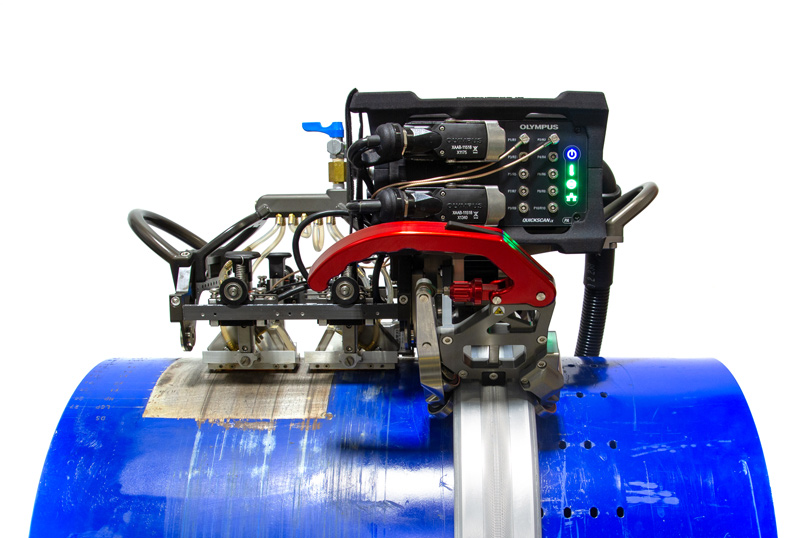

Visual assessment, often the first line of protection, permits for the recognition of surface problems such as cracks, damages, and porosity. Ultrasonic screening employs high-frequency sound waves to identify internal flaws, using a thorough analysis of weld integrity. This non-destructive approach is especially reliable for recognizing discontinuities that might not be noticeable externally.

Radiographic testing includes making use of X-rays or gamma rays to produce photos of the welded joint, disclosing internal flaws. This technique offers thorough understandings but may need specific equipment and safety and security considerations. Finally, magnetic bit testing works for identifying surface area and near-surface discontinuities in ferromagnetic materials, using magnetic fields and fine iron fragments.

Market Requirements and Laws

Compliance with industry requirements and laws is vital for ensuring the high quality and security of pipeline welding examinations. These criteria offer a framework for ideal methods in welding procedures, products, and assessment strategies, permitting companies to minimize problems and enhance the honesty of pipe systems. Key bodies such as the American Culture of Mechanical Designers (ASME), the American Welding Society (AWS), and the International Company for Standardization (ISO) collection forth guidelines that are extensively acknowledged and taken on within the industry.

In the USA, guidelines from the Pipe and Hazardous Materials Safety And Security Administration (PHMSA) govern the security of pipeline procedures, mandating extensive evaluation procedures. These criteria not just offer to safeguard public safety and the atmosphere however likewise make certain compliance with legal and lawful commitments. Adherence to the appropriate codes, such as ASME B31.3 for process piping, is crucial for keeping functional performance and regulative compliance.

Furthermore, continual updates and alterations to these requirements show technological developments and developing industry methods, highlighting the demand for companies to remain informed and train workers appropriately. Ultimately, durable compliance with recognized standards cultivates trust fund and reliability in pipeline facilities, guarding both assets and stakeholders.

Reliable Inspection Procedures

Efficient assessment treatments are crucial for identifying web potential problems in pipeline welds and making certain the overall integrity of the system. A systematic method to assessment incorporates numerous vital stages, including pre-weld, in-process, and post-weld evaluations. Each phase plays a vital role in keeping quality control.

During pre-weld assessment, it is vital to evaluate the products and joint setups, ensuring compliance with task specs. In-process assessments involve keeping track of welding methods and criteria, such as warmth input and take a trip rate, to avoid flaws from happening. This stage permits real-time adjustments to welding techniques.

Post-weld examinations consist of non-destructive testing (NDT) techniques like radiography, ultrasonic screening, and magnetic fragment testing. These methods aid identify inner and surface defects that can endanger the pipeline's functionality. Documents of all examination tasks is extremely important, giving a deducible record that supports conformity with market requirements.

Training and accreditation of assessment employees better improve the efficiency of these treatments. By adhering to a structured evaluation method, companies can mitigate threats, guarantee conformity, and eventually deliver pipelines that satisfy stringent security and performance demands.

Common Obstacles and Solutions

Pipeline welding assessment presents a number of common obstacles that can impact the top quality and security of the final item. One significant obstacle is the variability in welding strategies and materials, which can lead to irregular weld high quality. To address this, it is crucial to develop standardized treatments and training for welders, making certain an uniform technique across jobs.

Ecological elements, consisting of temperature level and humidity, can additionally affect the welding procedure, possibly resulting in cracks or insufficient fusion. Executing regulated atmospheres and sticking to pre-weld procedures can mitigate these threats.

Final Thought

Finally, the execution of best techniques for pipeline welding examination is vital for guaranteeing quality control and conformity with industry requirements. A comprehensive technique, incorporating numerous techniques such as aesthetic, ultrasonic, and radiographic screening, helps with the recognition of flaws throughout all phases of the welding process. Pipeline Welding Inspection. Adherence to developed regulations and find here efficient examination procedures not just enhances the dependability and safety and security of pipe systems but likewise mitigates dangers connected with welding problems, consequently advertising overall operational stability

Conformity with industry requirements and laws is important for making sure the quality and safety of pipe welding inspections. These requirements provide a framework for finest techniques in welding procedures, materials, and evaluation methods, permitting organizations to lessen issues and improve the stability of pipe systems.In the United States, laws from the Pipe and Hazardous Materials Safety Administration (PHMSA) regulate the security of pipeline operations, mandating extensive assessment procedures. An organized strategy to inspection incorporates numerous vital stages, consisting of pre-weld, in-process, and post-weld examinations.In verdict, the execution of ideal methods for pipeline welding evaluation is vital Recommended Reading for making sure high quality assurance and compliance with sector criteria.

Report this page